Selamat Datang

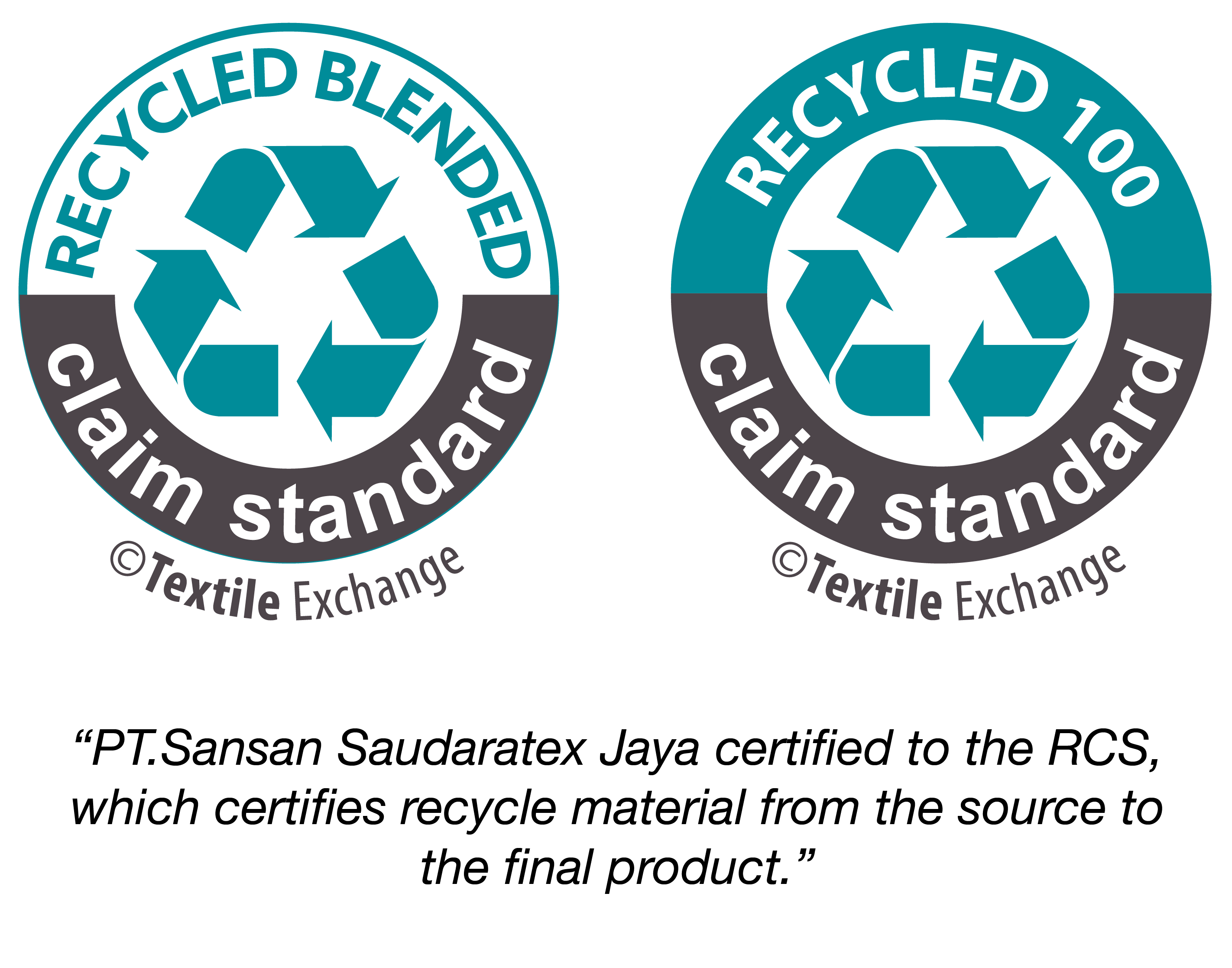

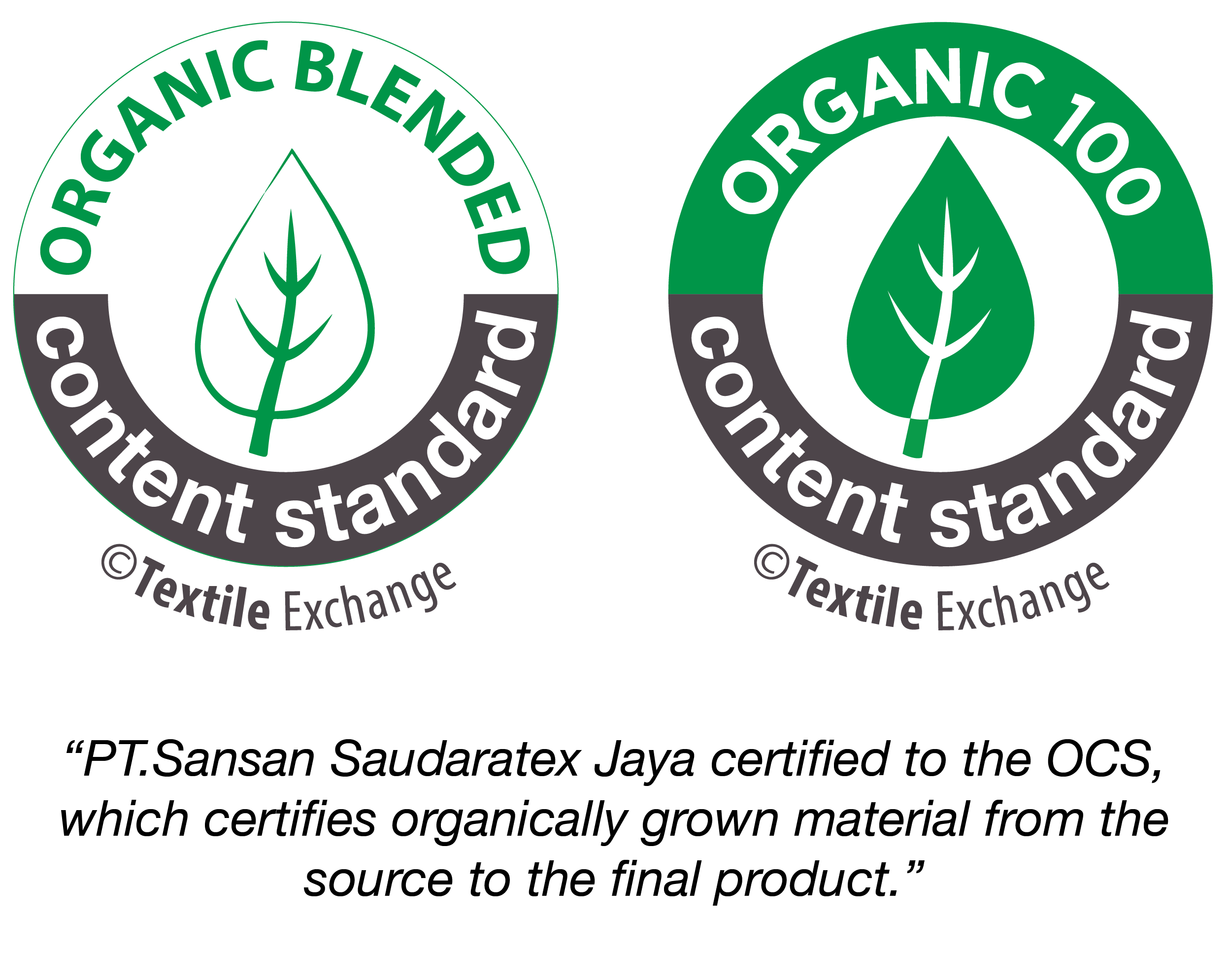

PT. SANSAN SAUDARATEX JAYA

Garmen & Tekstil

Didirikan pada tahun 1987 sebagai produsen dan eksportir Garmen & Tekstil

Selamat Datang

PT. SANSAN SAUDARATEX JAYA

Garmen & Tekstil

Didirikan pada tahun 1987 sebagai produsen dan eksportir Garmen & Tekstil

Selamat Datang

PT. SANSAN SAUDARATEX JAYA

Garmen & Tekstil

Didirikan pada tahun 1987 sebagai produsen dan eksportir Garmen & Tekstil

English

English